Windows and External Doorsets in accordance with EN 14351-1:2006 + A1:2010

Factory Product Control Manual

for

HOMEFRAME

Shadsworth Business Park

Partnership Way

Blackburn

BB1 2QP

Issued under the authority of the Management Representative: Mark Simm

Date of issue: 1st July 2012

Document issue number:

1: Introduction

This Factory Production Control (FPC) manual documents the processes and procedures involved with the manufacture of windows and external pedestrian doorsets without resistance to fire and/or smoke leakage characteristics to meet the requirements of EN 14351-1 for CE marking of the finished product.

The FPC is approved and issued under the responsibility of Phil Gregory who shall ensure that it is available to staff where it is relevant to their work and that they are familiar with it.

2: Quality System

The FPC System comprises of the following documents:

Factory Production Control Manual

It is the responsibility of all staff to identify any errors or omissions in the FPC and notify Phil Gregory who will undertake a review and make amendments if required.

2.1 Control of documents

It is the responsibility of Phil Gregory to ensure that all FPC system documents conform to the requirements of EN 14351-1.

Controlled copies of FPC Manual and any relevant procedures and standards are maintained on file and are stored on the shared drive on the computer system as a read only.

Any changes to the FPC shall first be reviewed and approved by Mark Simm. The updated FPC manual will be identified by the Document Issue No: in the header (sequential number starting at 1 for the first issue) and the relevant staff informed of the change.

No member of staff shall alter the FPC documents in any way. However, if they think that changes are required, they shall inform Phil Gregory who shall consider the proposal and make any necessary changes.

2.2 System review

An initial inspection of the factory and FPC was undertaken by Mark Simmand the results recorded. This inspection verified that:

Continuous surveillance and regular internal reviews are undertaken of the FPC system to ensure that it continues to meet the requirements of EN 14351-1 and the needs of the business.

Internal reviews are conducted annually. Mark Simm shall allocate auditors who are the most appropriate to undertake reviews of the activities, areas and associated documents to be assessed. A record of the audit is written which identifies areas of non-conformance and observations with recommendations for improvement.

Where corrective and/or preventive action is required, this shall be recorded and actioned within an agreed period.

The internal reviews will as a minimum check and record that:

3: Organisation

3.1 Management representative

The manufacturer has appointed Phil Gregoryto be the Management Representative for the manufacturing unit atHomeframe. The Management Representative is responsible for the conduct and supervision of factory production control procedures.

The Management Representative is also responsible for implementation and maintenance of this manual.

4: Scope of Products and Initial Type Testing

Homeframe specification – Casement window

70mm PVCu window profile

Steel Reinforced to manufacturers specification

High security locking (shoot bolt locking optional extra)

In line handle

Night vent security keeps

A or C rated double glazing

Homeframe specification – Tilt & Turn window

70mm PVCu window profile

Steel Reinforced to manufacturers specification

High security multipoint locking

Tilt & Turn handle

A or C rated double glazing

Homeframe specification – Vertical slider window

70mm PVCu window profile

Steel Reinforced to manufacturers specification

Balance operation mechanisms

Tilt and slide sashes

High security locking

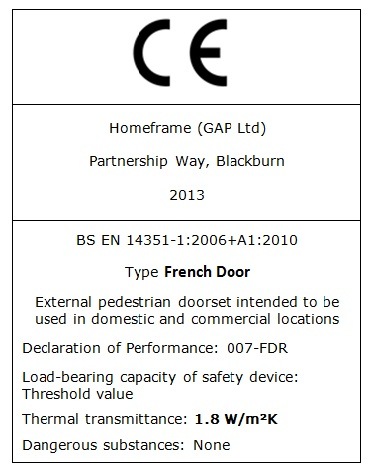

Homeframe specification – French door

70mm PVCu window profile

Steel Reinforced to manufacturers specification

Flag hinges

High security locking with hook and deadbolt to master

Top and bottom shoot bolt locking to slave

One piece keep and mullion

Door handle

Homeframe specification – Residential door

70mm PVCu window profile

Steel Reinforced to manufacturers specification

Flag hinges

High security locking with hook, deadbolt and shoot bolt

Door handle

5: Customer Ordering

The order processing for Homeframeis detailed below:

Orders received from customer (could be by fax, phone, email)

Order is processed to standard specification on our bespoke computer system. A unique job number is created known as a ‘GW’ number e.g. GW 1234 which is used for both frame and glass ordering.

Save the ‘GW Ledger’ once you have input all the information.

Quote saved as – ‘GW….Quotation’ and costing sheet saved as ‘GW…….Costs’

Confirmation is sent to customer by fax/email/phone.

Job file sent to Frame supplier which is identified by the GW number.

Job file sent to Glass supplier which is identified by the GW number.

Confirmations by return are checked and filed

GW ledger is completed – enter no. of items and date/time document received.

On receipt of the Frame and the glass the items are using the unique GW number and the specification is checked against the order confirmation.

6: Manufacturing

The manufacturing of Windows and Doorsets for Homeframeis detailed below:

7: Control of Non-conforming products

All significant non-conformances are reported to Phil Gregory for completion of a non-conformity report. The following procedure outlines the process.

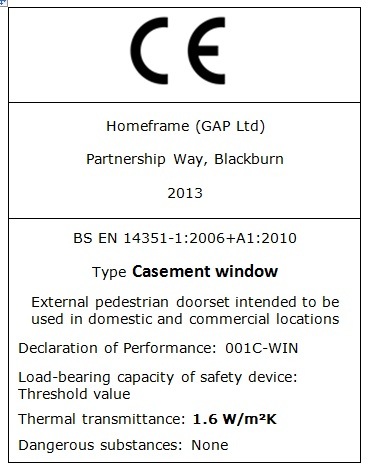

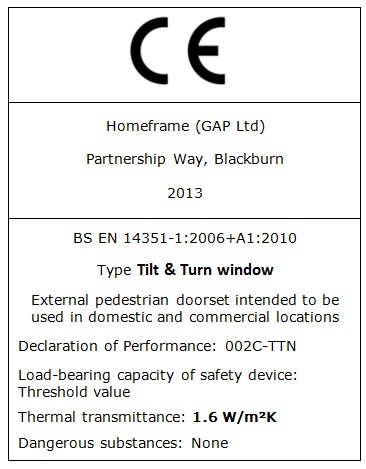

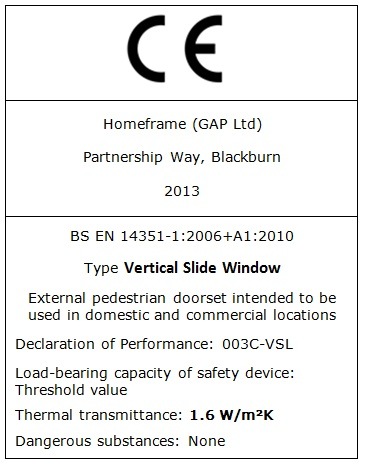

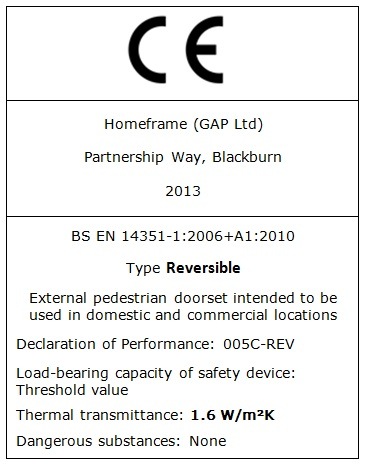

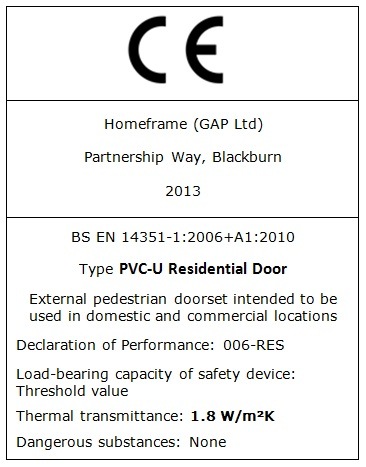

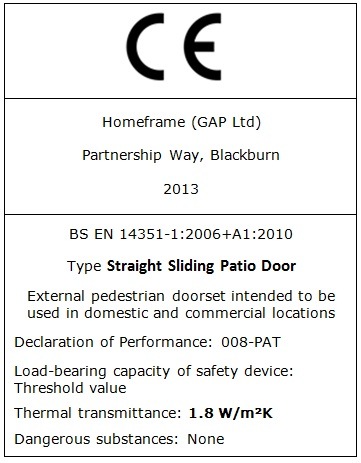

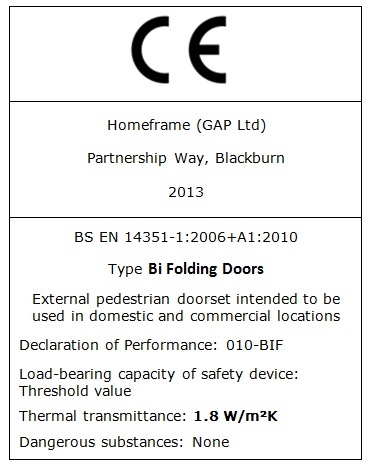

8: Labelling and marking

The packaging label will show the CE marking but this will be window specific. This can be achieved as all the information to identify which window it is, is held on our computer system. The following templates show how the Label will be printed with the relevant information for window style;

9: Training of personnel

A training matrix will be created to cross reference all personnel with current method statements. The training matrix will be updated on an on-going basis

Training can be undertaken in one of three ways:

a) The Manager provides an individual with training in a specific skill or area.

b) Employee requests to be trained in a certain area.

c) The Manager partners the employee with a fully skilled work mate, training is undertaken on the job.